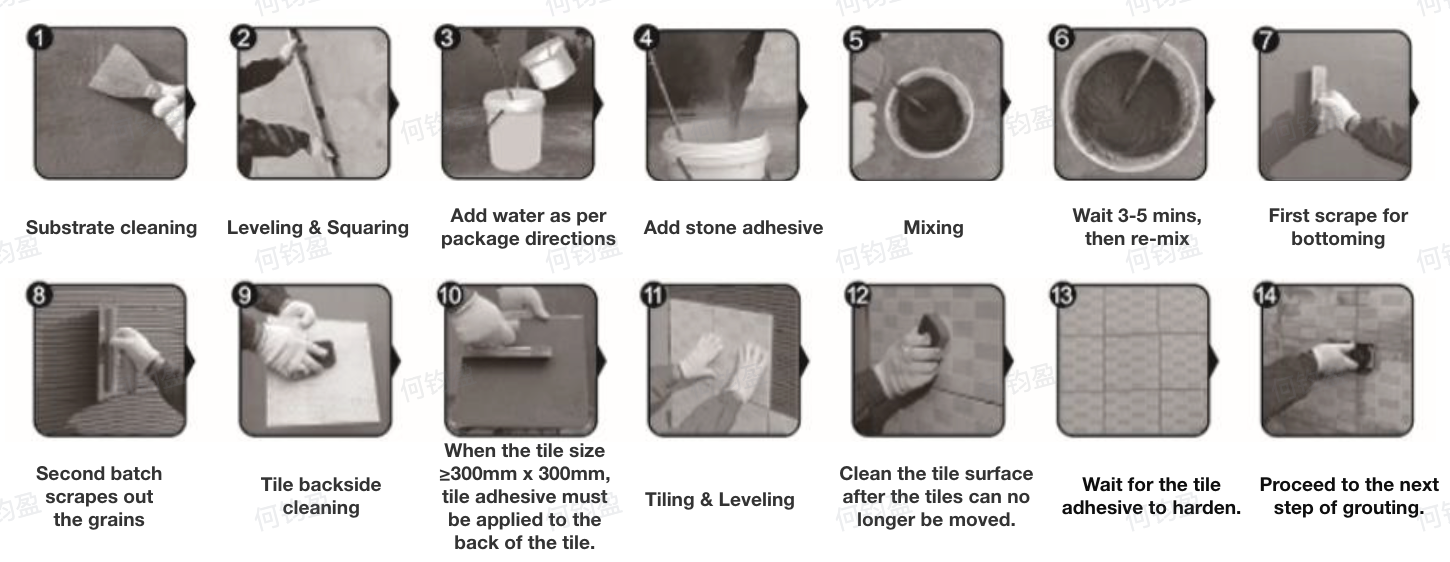

APPLICATION PROCEDURE

Preparation and Tools

Inspect the back of the tile for the presence of mold release agent or any other impurities that may affect tile adhesion. Ensure thorough cleaning. Prepare the following tools: electric mixer, mixing bucket, measuring cup, notched trowel, trowel, rubber mallet, level ruler, tape measure, chalk line box or laser level, tile cutter, sponge, tile spacers, and other necessary equipment.

Construction Process

· Substrate Treatment

The substrate must be solid, clean, free from oil, grease, wax stains, concrete curing agents, and other loose materials. The flatness of the substrate should not exceed 3mm/2 m.

· Adhesive Preparation

Follow the water mixing ratio indicated on the label.

Start by adding water to the mixing bucket, then gradually incorporate the powder while stirring with an electric mixer. Mix until a consistent and lump-free texture is achieved. Allow the mixture to rest for 3-5 minutes, then re-stir for 15-30 seconds. The prepared tile adhesive should be used within 2 hours.

· Tile Paving

Using a trowel, spread a thin but robust layer of tile adhesive onto the substrate's surface. Subsequently, apply a thicker layer of adhesive and utilize an appropriate notched trowel to comb through the tile adhesive layer. In adverse weather conditions (such as high temperatures, strong winds, etc.) or when the substrate exhibits high water absorption, tiles should be promptly installed. Before tiling, assess the tile adhesive's dryness by touching its surface with your finger. If the adhesive is still wet, tiles can be applied. However, if the adhesive is dry, reapplication is necessary. The depth of the notched trowel's teeth should be adjusted considering the levelness of the working surface and the variations in the tile back.

If the gaps on the back of the tile are substantial or if the tile size is equal to or greater than 300*300mm, the combination method should be employed for installation. This entails applying tile adhesive to both the substrate and the back of the tile, followed by combing, laying, and kneading the tile onto the adhesive layer.

· Application Guide

TECNICAL INFOMATION

|

Product Technical Parameters |

Packing Specification |

25kg |

|

Character |

Gray powder |

|

|

Executive Standard |

JC/T 547-2017 C1 |

|

|

Shelf life |

12 months when stored unopened in a cool, dry place. |

|

|

Construction Technical Parameters |

Airing Time |

20 min |

|

Operable Time |

2h |

|

|

Jointing Time |

24h(20~ 35℃) 2~3d(5~20℃) |

|

|

Construction Consumption |

Working temperature 5°C~35°C. Outdoor construction should be avoided in high temperature, frost, direct sunlight, or windy rainy weather. |

|

|

Reference Dosage |

1.5kg/㎡/mm Actual consumption depends on the flatness of the base and the construction method |

FEATURES AND BENEFITS

· Strong commonality

· High bonding strength

· Smooth and easy to apply during construction

· Environmentally friendly

PRODUCT INFOMATION

The product complies with the standard requirements of JC/T547-2017. The main indicators are as follows:

|

No. |

Test Item |

Technical Specification |

|

1 |

Tensile Adhesion Strength / MPa |

≥0.5 |

|

2 |

Tensile Adhesion Strength after Immersion / MPa |

≥0.5 |

|

3 |

Tensile Adhesion Strength after Heat Aging / MPa |

≥0.5 |

|

4 |

Tensile Adhesion Strength after Freeze-Thaw Cycle / MPa |

≥0.5 |

|

5 |

Tensile Adhesion Strength after Airing for ≥20min / MPa |

≥0.5 |

Suitable for the installation of ceramic tiles with a water absorption rate greater than 0.2% on stable indoor and outdoor walls and floors in buildings. The specific application scope is as follows:

|

Interior Applications |

Exterior Applications |

||||

|

Suitable Substrate |

Suitable Tiles |

Suitable Tile Size |

Suitable Substrate |

Suitable Tiles |

Suitable Tile Size |

|

Stable substrates such as cement mortar, concrete, brick walls, etc. |

High water absorption tiles (water absorption rate > 3%) |

≤600×600mm |

Stable substrates such as cement mortar, concrete, brick walls, etc. |

High water absorption tiles (water absorption rate > 3%) |

≤300mm×300mm |

|

Low water absorption tiles (water absorption rate 0.2~3%) |

≤300mm×600mm |

Low water absorption tiles (water absorption rate 0.2~3%) |

≤100mm×200mm |

||

Strong commonality

Strong commonality High bonding strength

High bonding strength Smooth and easy to apply during construction

Smooth and easy to apply during construction Environmentally friendly

Environmentally friendly